Solution

In order to remove a large number of baked goods from a non-stop conveyor belt and place them in baskets, bearing components made of plastic are now used in the modern packaging plant instead of the conventional metal bearings. Specifically,

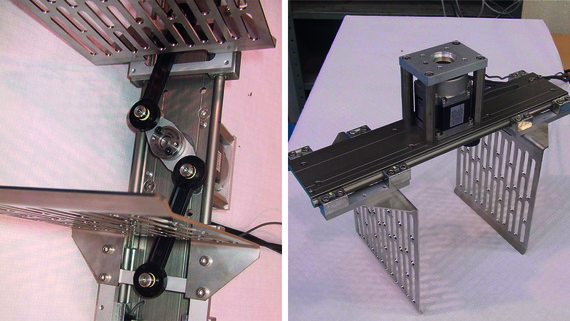

drylin W linear rails are used here, on which matching

drylin W carriages travel. In addition to the precise and quiet bearings,

double joints made of the material igubal have also been installed. While the drylin bearings enable the linear movement of the gripper, the igubal components ensure the constant pivoting movement of the two gripper arms. Due to the high-performance polymers used as materials in both the linear and rotary bearing elements, they are completely lubrication and maintenance-free. This is because the polymers are self-lubricating and therefore meet the high hygiene requirements in the plant.